2025-01-14 Pipe extrusion machines provide numerous benefits for manufacturers in producing high-quality pipes efficiently and economically. Below are the key advantages:1. Versatile Production Capabilities • Diverse Materials: Can process various thermoplastics like PVC, PE, PP, HDPE, and more. • Wide Applica

Read More

2025-01-14 The evolution of pipe extrusion technology reflects advancements in materials, machinery, and process controls, enabling the production of high-quality, efficient, and diverse piping systems. Below is an overview of the significant stages in the development of pipe extrusion technology:1. Early Deve

Read More

2025-01-13 A PVC water pipe extrusion line consists of several components working together to manufacture high-quality PVC pipes efficiently. Below are the main components and their functions:1. Hopper Loader and Feeder • Purpose: Automatically feeds raw PVC material (resin and additives) into the extruder. •

Read More

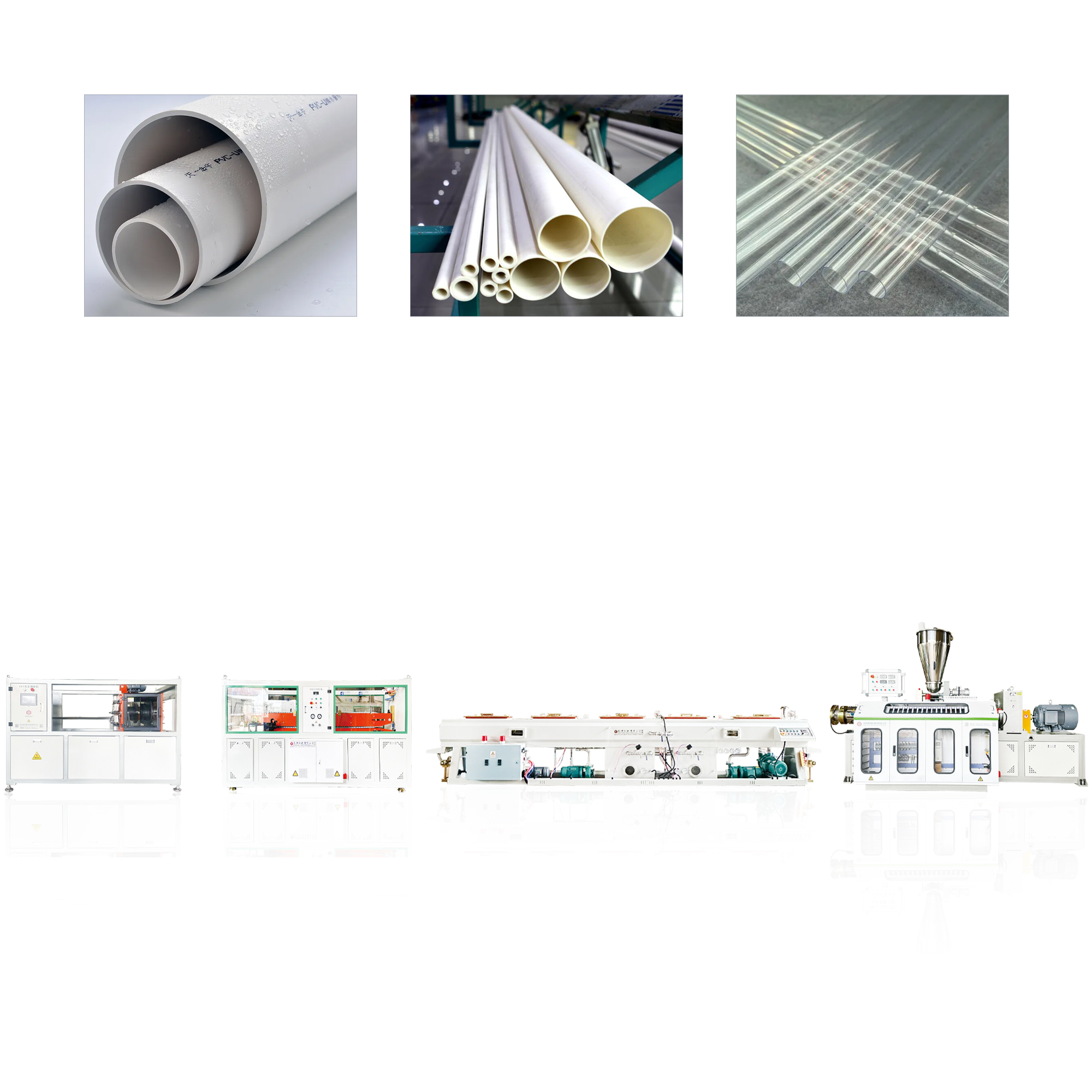

2025-01-13 PVC (Polyvinyl Chloride) water pipes offer numerous advantages that make them a popular choice for residential, commercial, and industrial plumbing systems. Here are the key benefits:1. Durability and Longevity • PVC pipes are resistant to corrosion, rust, and chemical damage, ensuring a long servic

Read More

2025-01-11 Haul-off unit machines are classified based on their pulling mechanisms and design, each suited for specific materials and applications. Here are the different types of haul-off unit machines and their applications:1. Belt-Type Haul-Off Machines • Description: Use one or multiple belts to grip and p

Read More

2025-01-11 Haul-off unit machines consist of several key components, each serving specific functions to ensure smooth and efficient operation in extrusion processes. Here’s an overview of the main components and their functions:1. Pulling Mechanism • Types: Belts, caterpillar tracks, rollers, or vacuum systems

Read More

2025-01-11 Maximizing the efficiency of haul-off unit machines is key to improving productivity, reducing downtime, and maintaining high-quality output in extrusion processes. Here are practical tips to enhance their efficiency:1. Choose the Right Machine for the Job • Select a haul-off unit that matches the p

Read More

2025-01-11 Proper maintenance and care for haul-off unit machines are essential to ensure their longevity, reliable performance, and consistent product quality. Here’s a comprehensive guide to maintaining and caring for haul-off units:1. Regular Inspection • Daily Checks: Inspect belts, tracks, rollers, and ot

Read More

2025-01-11 Choosing the right haul-off unit machine for your extrusion process is crucial to achieving optimal performance, product quality, and operational efficiency. Here are the key factors to consider:1. Material Type • Determine the material properties (e.g., rigid, flexible, soft, or sensitive) to ensur

Read More

2025-01-11 Using haul-off unit machines in extrusion processes offers several advantages, contributing to efficiency, product quality, and operational consistency. Here are the key benefits:1. Consistent Material Pulling • Ensures uniform pulling speed throughout the extrusion process, reducing variations in p

Read More