2025-01-16 The Importance of PE Extrusion in the Plastic Manufacturing IndustryPolyethylene (PE) extrusion is a cornerstone process in the plastic manufacturing industry, playing a crucial role in producing versatile and durable products. It has become a key technology due to its efficiency, scalability, and a

Read More

2025-01-16 Common Challenges and Troubleshooting in PE (Polyethylene) ExtrusionThe PE extrusion process can face a variety of challenges that affect product quality, production efficiency, or machine performance. Understanding the root causes and implementing effective solutions are key to ensuring consistent

Read More

2025-01-16 Steps in the PE (Polyethylene) Extrusion ProcessThe PE extrusion process involves a systematic sequence of steps that transform polyethylene raw materials into finished pipes with precise dimensions and quality. Below is a detailed step-by-step guide to the process:1. Raw Material Preparation • Poly

Read More

2025-01-16 The production of PE pipes through extrusion requires a series of specialized machines and auxiliary equipment to handle each step of the process efficiently. Below is a breakdown of the essential equipment and their functions:1. Raw Material Handling Equipment • Hopper Loader: • Automatically feeds

Read More

2025-01-16 PE extrusion is a process of producing continuous lengths of polyethylene pipes by melting and shaping PE resin through an extrusion machine. Polyethylene is widely used in applications such as water pipes, gas pipes, irrigation systems, and cable conduits due to its strength, flexibility, and chemi

Read More

2025-01-14 Pipe extrusion machines come in various types, each tailored to produce specific types of pipes using different materials and production techniques. Below are the main types of pipe extrusion machines and their applications:1. Single-Screw Extrusion Machines • Description: Uses a single rotating scr

Read More

2025-01-14 Key Components and Working Principle of Pipe Extrusion MachinesPipe extrusion machines are designed to produce continuous lengths of pipes with uniform dimensions and properties. They operate based on a systematic process involving the melting, shaping, and cooling of raw materials. Below is a detai

Read More

2025-01-14 Pipe extrusion machines provide numerous benefits for manufacturers in producing high-quality pipes efficiently and economically. Below are the key advantages:1. Versatile Production Capabilities • Diverse Materials: Can process various thermoplastics like PVC, PE, PP, HDPE, and more. • Wide Applica

Read More

2025-01-14 The evolution of pipe extrusion technology reflects advancements in materials, machinery, and process controls, enabling the production of high-quality, efficient, and diverse piping systems. Below is an overview of the significant stages in the development of pipe extrusion technology:1. Early Deve

Read More

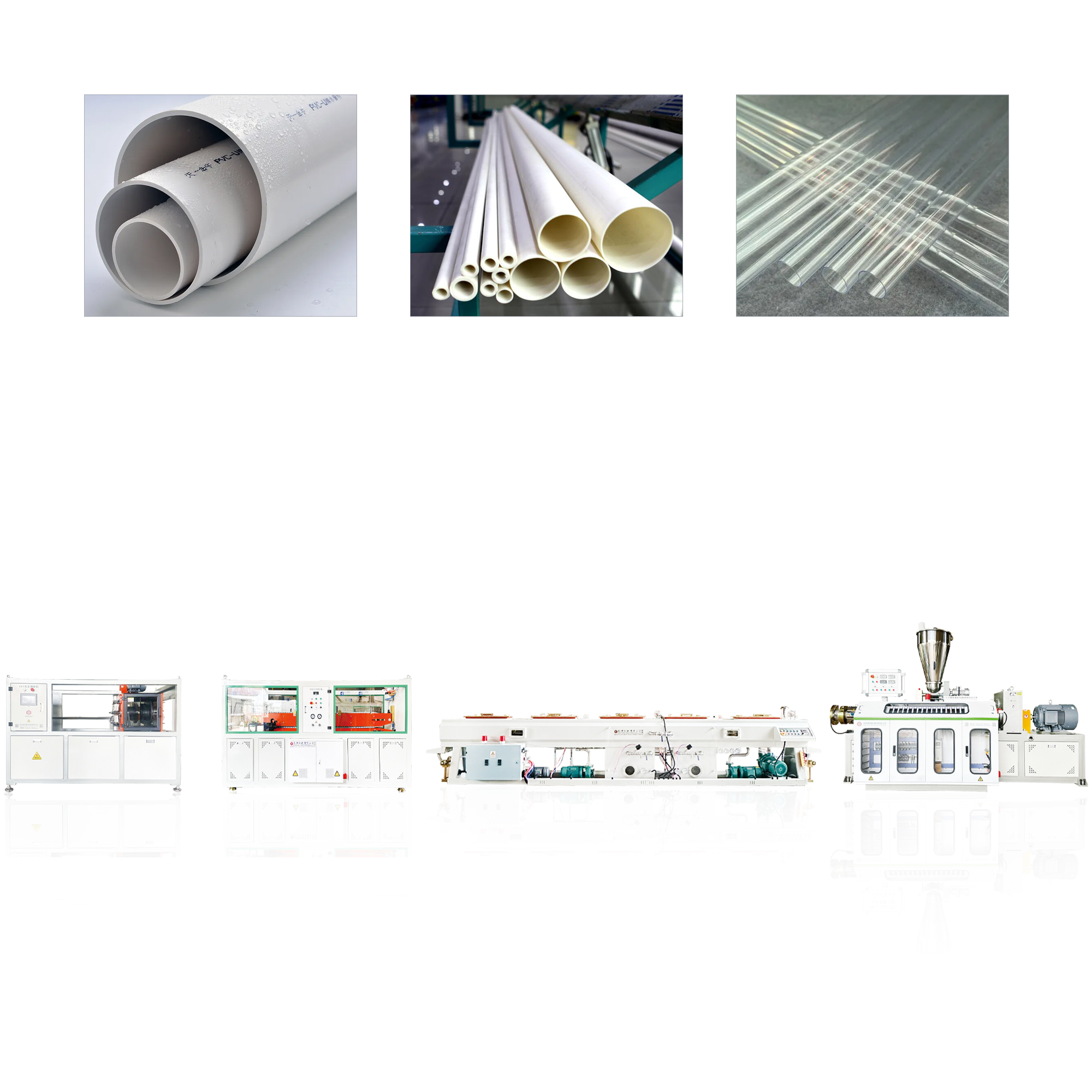

2025-01-13 A PVC water pipe extrusion line consists of several components working together to manufacture high-quality PVC pipes efficiently. Below are the main components and their functions:1. Hopper Loader and Feeder • Purpose: Automatically feeds raw PVC material (resin and additives) into the extruder. •

Read More