2025-01-11 Haul-off unit machines are classified based on their pulling mechanisms and design, each suited for specific materials and applications. Here are the different types of haul-off unit machines and their applications:1. Belt-Type Haul-Off Machines • Description: Use one or multiple belts to grip and p

Read More

2025-01-11 Haul-off unit machines consist of several key components, each serving specific functions to ensure smooth and efficient operation in extrusion processes. Here’s an overview of the main components and their functions:1. Pulling Mechanism • Types: Belts, caterpillar tracks, rollers, or vacuum systems

Read More

2025-01-11 Maximizing the efficiency of haul-off unit machines is key to improving productivity, reducing downtime, and maintaining high-quality output in extrusion processes. Here are practical tips to enhance their efficiency:1. Choose the Right Machine for the Job • Select a haul-off unit that matches the p

Read More

2025-01-11 Proper maintenance and care for haul-off unit machines are essential to ensure their longevity, reliable performance, and consistent product quality. Here’s a comprehensive guide to maintaining and caring for haul-off units:1. Regular Inspection • Daily Checks: Inspect belts, tracks, rollers, and ot

Read More

2025-01-11 Choosing the right haul-off unit machine for your extrusion process is crucial to achieving optimal performance, product quality, and operational efficiency. Here are the key factors to consider:1. Material Type • Determine the material properties (e.g., rigid, flexible, soft, or sensitive) to ensur

Read More

2025-01-11 Using haul-off unit machines in extrusion processes offers several advantages, contributing to efficiency, product quality, and operational consistency. Here are the key benefits:1. Consistent Material Pulling • Ensures uniform pulling speed throughout the extrusion process, reducing variations in p

Read More

2025-01-11 Haul-off units are crucial in extrusion processes, where they pull extruded materials (like pipes, tubes, profiles, or sheets) at a consistent speed to maintain quality and ensure dimensional accuracy. There are various types of haul-off unit machines, categorized based on their design, application,

Read More

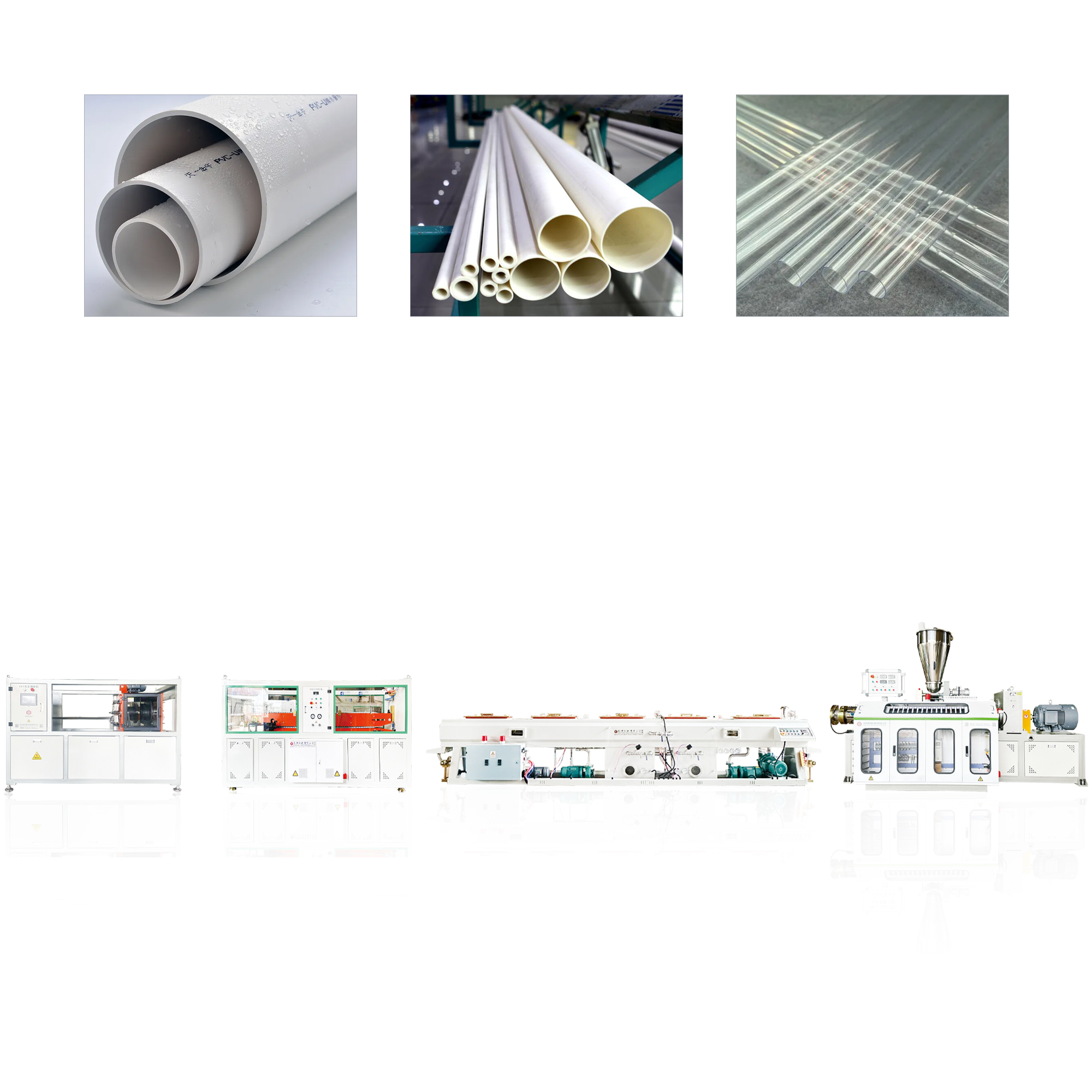

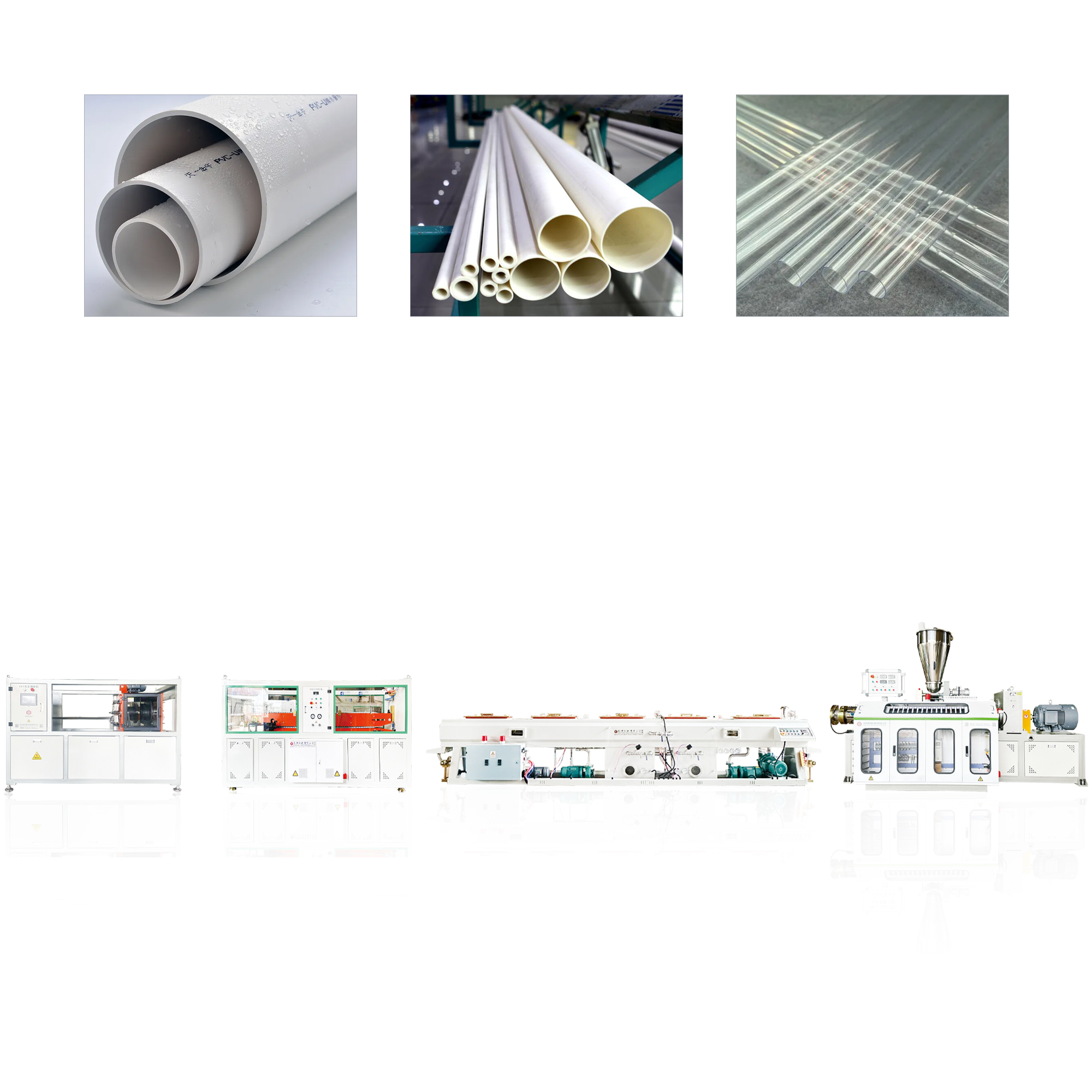

2025-01-10 PVC (Polyvinyl Chloride) pipes manufactured using extrusion lines are widely used in various industries due to their excellent properties and versatility. Below are the key advantages and common applications of these pipes.Advantages of PVC Pipes Produced by Extrusion Lines1. Durability and Longevit

Read More

2025-01-10 Regular maintenance and effective troubleshooting of PVC pipe extrusion lines are essential for ensuring consistent production, minimizing downtime, and extending equipment lifespan. Below is a comprehensive guide to maintaining and troubleshooting PVC pipe extrusion lines.Regular Maintenance Tips1.

Read More

2025-01-10 Common Challenges in PVC Pipe Extrusion and How to Overcome ThemThe PVC pipe extrusion process is a complex operation that requires precision and control to produce high-quality pipes. However, various challenges can arise during production, affecting efficiency, quality, and output. Here are some c

Read More