▏Product Vedio

▏Product Introduction

>> Plastic PVC pelletizing production line

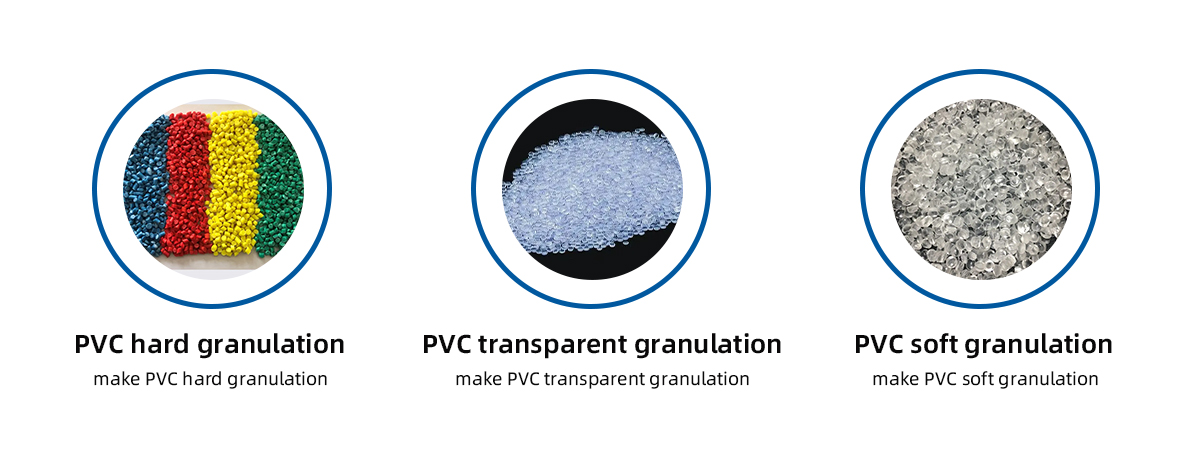

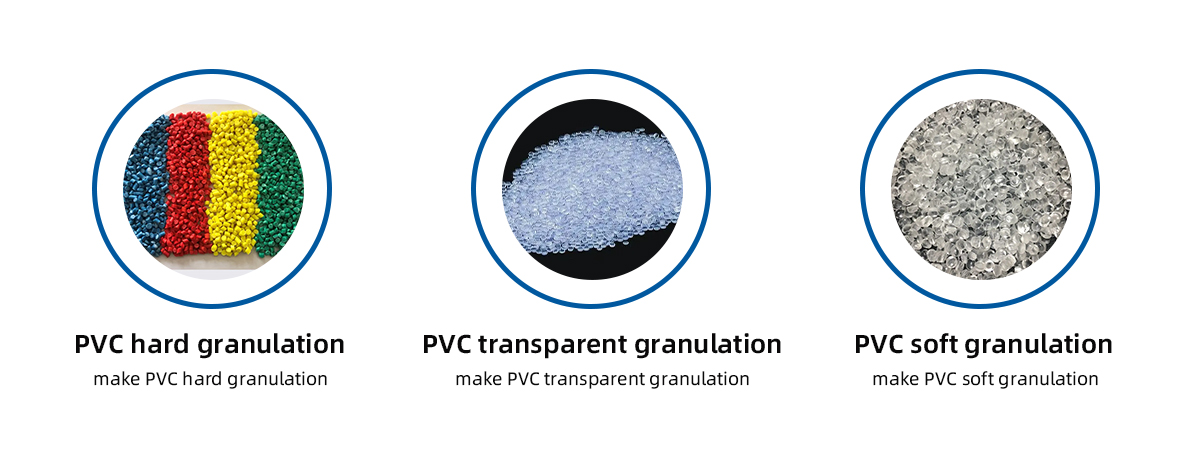

The Plastic PVC pelletizing production line is a equipment specially used to process polyvinyl chloride (PVC) raw materials into pellets. The production line adopts die surface heating mode and has the characteristics of unique structure, high degree of automation, convenient operation and stable and reliable continuous production.

▏Range Of Application

▏Technical Parameters

Production line configuration | Quantity | Detail |

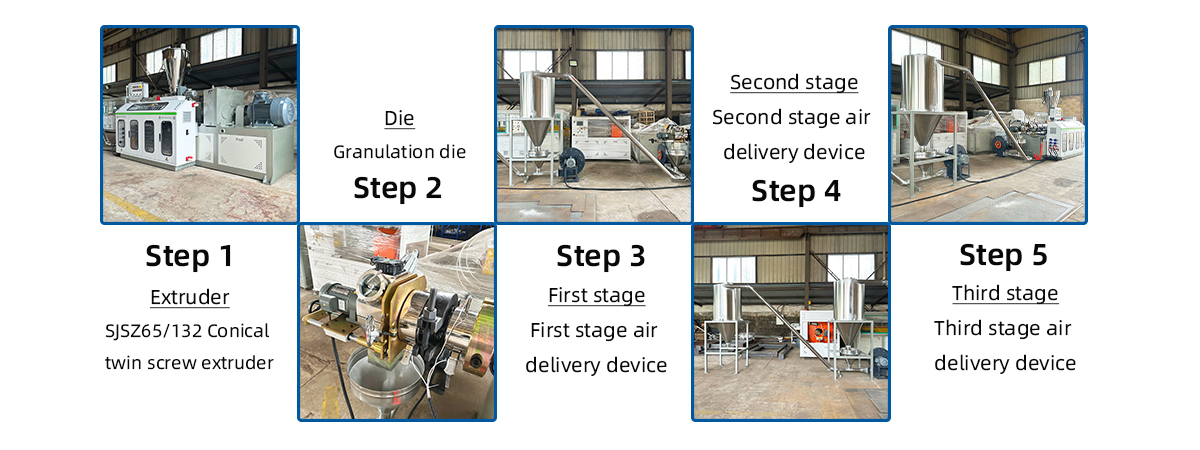

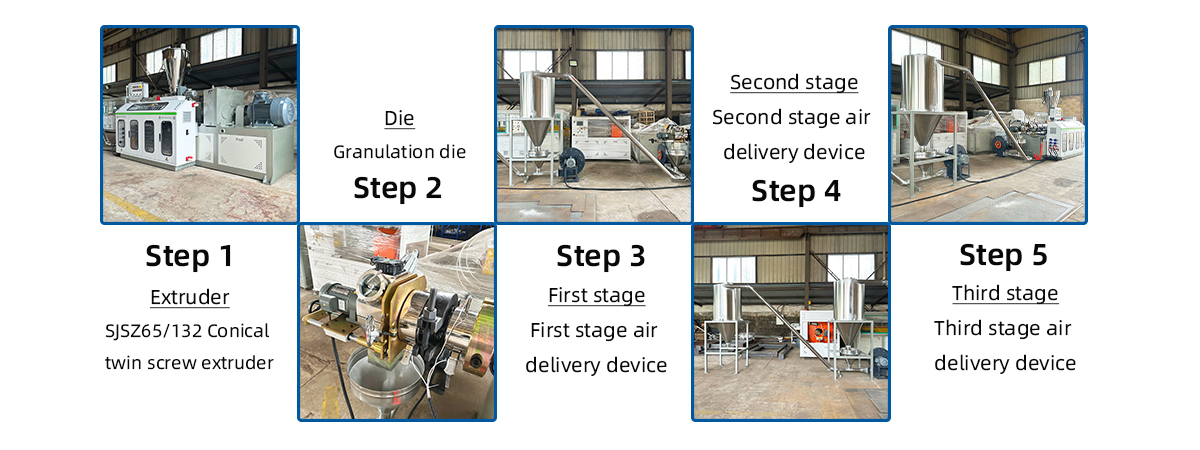

SJZ65/132 Conical twin screw extruder | 1 set | Material 38CrMoAlA |

PVC hot granulation mold | 1 set | Die surface hot grain |

Level 3 air delivery device | 1 set | 3KW Air blower |

Cyclone separation bin | 1 set | Stainless steel |

Vibrating screen | 1 set | Vibrating machine |

▏Production Procedure

▏Product Photos

▏Plastic PVC Pelletizing Machine: Revolutionizing Polymer Processing

The Plastic PVC pelletizing machine is a cornerstone of modern polymer manufacturing. Designed to transform raw PVC (polyvinyl chloride) materials into uniform pellets, this equipment plays a pivotal role in streamlining production processes for industries ranging from construction to packaging. With the growing demand for recyclable and reusable plastics, PVC pelletizing machines have become indispensable for achieving efficiency, consistency, and sustainability.

How a Plastic PVC Pelletizing Machine Works

| 1 | Extrusion Process |

| The first stage involves feeding raw PVC compounds—often a mix of resin, stabilizers, plasticizers, and additives—into an extruder. The machine heats and melts the material, homogenizing it into a viscous fluid. Twin-screw extruders are commonly used for PVC due to their superior mixing capabilities and temperature control. |

| 2 | Cooling and Cutting |

| Once extruded, the molten PVC is forced through a die to form strands or sheets. These are rapidly cooled using water baths or air systems to solidify the structure. A high-speed rotary cutter then slices the strands into uniform pellets, typically 2–5 mm in diameter. |

| 3 | Collection and Packaging |

| The pellets are dried to remove residual moisture and screened to eliminate irregular-sized particles. Finally, they are packaged for storage or shipment to downstream manufacturers. |

Applications of PVC Pellets

| 1 | Construction Industry |

| PVC pellets are widely used to produce pipes, window frames, and vinyl flooring. Their durability, chemical resistance, and cost-effectiveness make them ideal for long-lasting infrastructure. |

| 2 | Automotive and Electronics |

| From wire insulation to dashboard components, PVC pellets provide lightweight, flame-retardant solutions that meet stringent safety standards. |

| 3 | Medical and Packaging |

| Medical tubing and blister packaging rely on high-purity PVC pellets manufactured under controlled conditions to ensure compliance with hygiene regulations. |

Advantages of Using a Plastic PVC Pelletizing Machine

| 1 | Enhanced Material Consistency |

| By converting raw PVC into uniform pellets, manufacturers achieve precise control over material properties such as density, melt flow, and additive dispersion. This consistency minimizes defects in final products. |

| 2 | Waste Reduction and Recycling |

| Pelletizing machines enable reprocessing of PVC scrap, reducing landfill waste. Recycled pellets can be blended with virgin materials, lowering production costs and environmental impact. |

| 3 | Scalability and Automation |

| Modern pelletizers integrate with IoT-enabled systems, allowing real-time monitoring of parameters like temperature and throughput. This automation boosts productivity for large-scale operations. |

Key Considerations When Choosing a Plastic PVC Pelletizing Machine

| 1 | Throughput Capacity |

| Match the machine’s output (e.g., 500 kg/h vs. 2,000 kg/h) to your production goals. Overestimating capacity can lead to unnecessary energy costs. |

| 2 | Material Compatibility |

| Ensure the machine handles your specific PVC formulation. For example, rigid PVC requires higher torque extruders than flexible variants. |

| 3 | Energy Efficiency |

| Look for features like variable frequency drives (VFDs) and heat recovery systems to minimize power consumption. |

| 4 | Maintenance Requirements |

| Opt for pelletizers with easy-access components and corrosion-resistant materials to reduce downtime. |

Maintenance Tips for Optimal Performance

| 1 | Regular Cleaning |

| Residual PVC can accumulate in dies and cutters, causing blockages. Schedule routine cleaning using non-abrasive methods to prevent degradation. |

| 2 | Lubrication and Wear Inspection |

| Check screws, barrels, and bearings for wear. Proper lubrication extends the lifespan of moving parts. |

| 3 | Calibration and Software Updates |

| Periodically calibrate temperature sensors and cutter speeds. Update control software to leverage performance-enhancing algorithms. |

Future Trends in PVC Pelletizing Technology

| 1 | Eco-Friendly Innovations |

| Manufacturers are developing pelletizers that consume less energy and accommodate bio-based PVC blends. Closed-loop water cooling systems are also gaining traction to reduce water waste. |

| 2 | Smart Manufacturing Integration |

| AI-driven predictive maintenance and blockchain-based material tracking are poised to revolutionize PVC pellet production, ensuring transparency and quality assurance. |

The Plastic PVC pelletizing machine is more than just a processing tool—it’s a catalyst for sustainable, efficient manufacturing. By understanding its mechanics, applications, and maintenance needs, businesses can optimize their operations while contributing to a circular economy. As technology evolves, these machines will continue to shape the future of the plastics industry.

| 1 | The production process |

| The production process is roughly as follows: the raw material is first processed by the twin-screw extruder, and then enters the die surface heat machine through the cutting die head for heat treatment. The heated PVC particles are cooled by multi-channel forced cooling air, then screened by vibration screening, and finally entered the storage bin for storage. |

| 1 | the conical twin-screw extruder |

| Among them, the conical twin-screw extruder is one of the key equipment of the production line, which has large output and high efficiency, and is equipped with advanced temperature control meter and frequency conversion speed regulation technology to ensure the efficient and stable production process. At the same time, the unique die surface cutting structure makes the cutting speed adjustable, high precision, and safe and convenient use. |

The plastic PVC pelletizing production line is suitable for large-scale, continuous production of PVC particles, can meet the demand for PVC particles in different fields, and is widely used in plastic processing, pipe manufacturing, building materials and other industries.

▏Product Advantage

| 1 | Efficient production |

| The plastic PVC pelletizing production line adopts advanced heating technology, which can achieve high-speed and efficient particle manufacturing to meet the needs of large-scale production. |

| 2 | High precision granulation |

| the die surface heat method makes the granulation precision high, ensures the uniformity and consistency of the particles, and helps to improve the quality of downstream products. |

| 3 | Continuous and stable operation |

| The plastic PVC pelletizing production line is reasonably designed and the components are closely coordinated to achieve continuous and stable operation, reducing downtime and maintenance costs. |

| 4 | High degree of automation |

| The plastic PVC pelletizing production line is equipped with advanced automatic control system, which reduces manual intervention and improves the reliability and stability of the production process. |

| 5 | Easy operation |

| The plastic PVC pelletizing production line is simple and easy to master, even for non-professionals can quickly get started, reducing the difficulty and cost of operation. |

| 6 | Strong adaptability of raw materials |

| The plastic PVC pelletizing production line can handle various types of PVC raw materials, strong adaptability, and can meet different customer and production needs. |

| 7 | Energy saving and environmental protection |

| energy saving and environmental protection factors are fully considered in the design and operation of the plastic PVC pelletizing production line, and advanced energy-saving technology and environmentally friendly materials are used to reduce energy consumption and emissions. |

| 8 | Easy maintenance |

| Each part of the plastic PVC pelletizing production line is reasonably designed, easy to maintain and replace, reducing the difficulty and cost of maintenance. |

| 9 | Safe and reliable |

| The plastic PVC pelletizing production line is equipped with multiple safety protection devices, such as overload protection, temperature control, etc., to ensure the safety of the production process. |

| 10 | Good scalability |

| The plastic PVC pelletizing production line can be expanded and upgraded as needed to meet the needs of future production scale and technological development. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping