▏Product Vedio

▏Product Introduction

▏Main Details

▏Product Photos

▏Drying Mixer: The Ultimate Solution for Efficient Drying and Mixing

The Drying Mixer is a state-of-the-art industrial equipment designed to seamlessly integrate drying and mixing processes into a single, efficient operation. Ideal for industries such as pharmaceuticals, food processing, chemicals, and ceramics, this versatile machine combines advanced drying technology with precise mixing capabilities to deliver consistent, high-quality results. Whether you're working with powders, granules, or viscous materials, the Drying Mixer ensures optimal performance, reduced processing time, and enhanced product quality.

Key Features

| 1 | Dual-Function Design |

| The Drying Mixer eliminates the need for separate drying and mixing equipment by combining both functions into one compact unit. This not only saves space but also reduces energy consumption and operational costs. |

| 2 | Advanced Drying Technology |

| Equipped with efficient heating systems (such as hot air, vacuum, or steam), the Drying Mixer ensures uniform heat distribution for consistent drying results. It is capable of handling heat-sensitive materials without compromising their integrity. |

| 3 | Precision Mixing |

| The mixer features a robust agitator and specially designed blades that ensure homogeneous blending of materials. Whether you're mixing dry powders or wet pastes, the Drying Mixer delivers unparalleled consistency. |

| 4 | Durable Construction |

| Built with high-quality stainless steel, the Drying Mixer is resistant to corrosion, wear, and chemical damage. Its robust design ensures long-lasting performance even in demanding industrial environments. |

| 5 | User-Friendly Operation |

| The Drying Mixer is designed with ease of use in mind. It features an intuitive control panel for precise adjustment of temperature, mixing speed, and drying time. Safety mechanisms, such as overload protection and emergency stop functions, ensure safe and reliable operation. |

| 6 | Hygienic and Easy to Clean |

| With smooth surfaces and minimal dead zones, the Drying Mixer meets stringent hygiene standards, making it ideal for industries like pharmaceuticals and food processing. Its modular design simplifies cleaning and maintenance, reducing downtime. |

| 7 | Customizable Options |

| The Drying Mixer is available in various sizes and configurations to meet specific production needs. Options include different heating methods, mixing blade designs, and material compatibility. |

Applications

The Drying Mixer is a versatile solution for a wide range of industries and applications:

- Pharmaceuticals: Drying and mixing of active pharmaceutical ingredients (APIs) and excipients.

- Food Processing: Blending and drying of spices, flavors, and food additives.

- Chemicals: Homogenization and drying of chemical powders and granules.

- Ceramics: Mixing and drying of ceramic raw materials.

- Plastics: Drying and dispersion of polymer resins and additives.

Why Choose the Drying Mixer?

| 1 | Enhanced Efficiency |

| By combining drying and mixing into a single process, the Drying Mixer significantly reduces processing time and energy consumption, boosting overall productivity. |

| 2 | Consistent Quality |

| The precise control over drying and mixing parameters ensures uniform product quality, batch after batch. |

| 3 | Cost-Effective Solution |

| The integration of two processes into one machine reduces capital investment, operational costs, and maintenance requirements. |

| 4 | Reliability and Durability |

| Built to withstand harsh industrial conditions, the Drying Mixer offers unmatched reliability and a long service life. |

| 5 | Sustainability |

| With energy-efficient drying systems and reduced material waste, the Drying Mixer supports sustainable manufacturing practices. |

Technical Specifications

- Capacity: Available in various sizes to suit different production volumes.

- Heating Methods: Hot air, vacuum, steam, or electric heating options.

- Mixing Speed: Adjustable speed for precise control over mixing intensity.

- Material Compatibility: Suitable for powders, granules, and viscous materials.

- Construction Material: High-grade stainless steel (SS304 or SS316).

The Drying Mixer is the ultimate solution for industries seeking to optimize their drying and mixing processes. With its advanced technology, robust design, and user-friendly features, it delivers unmatched performance, efficiency, and product quality. Whether you're looking to streamline production, reduce costs, or meet strict industry standards, the Drying Mixer is the ideal choice for your needs.

Invest in the Drying Mixer today and experience the perfect blend of innovation, reliability, and precision in your production process!

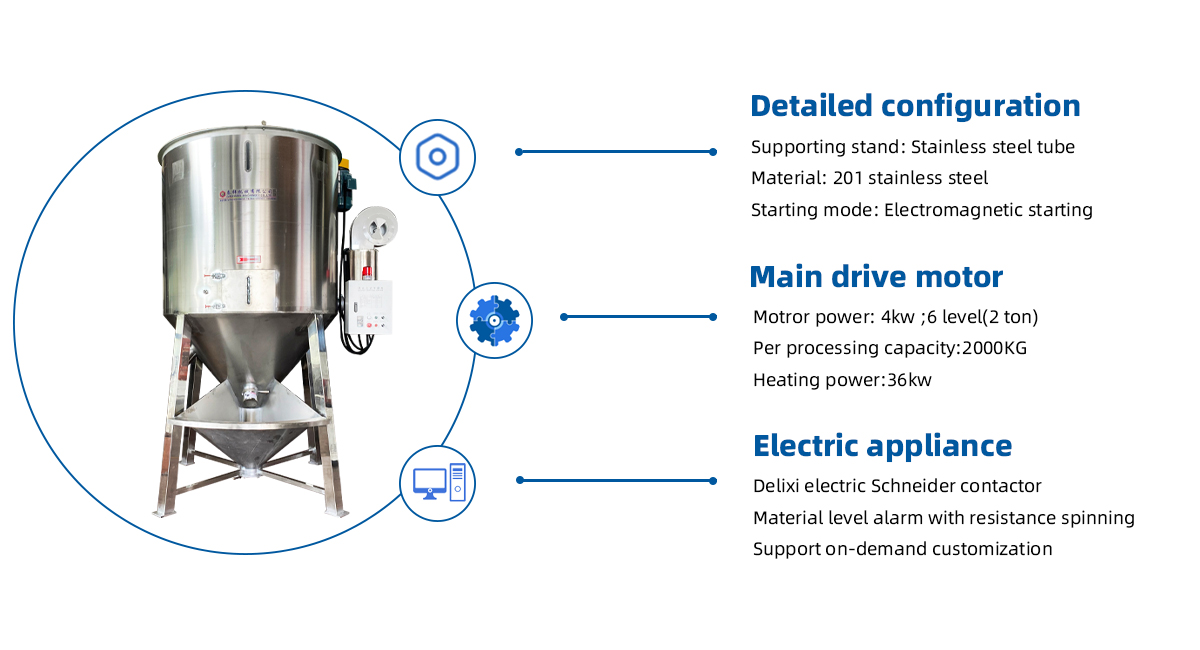

| 1 | Overview |

| Plastic Dryer Mixer With Heating machine is a kind of equipment that combines mixing and drying functions. Through a specific stirring device and drying system, the wet material is heated and evaporated at the same time of stirring, so as to quickly and effectively remove excess water in the material and obtain a dry and uniform mixture. |

| 2 | the working principle |

| The working principle of the drying mixer mainly includes two processes: mixing and drying. 1. Mixing process: driven by the motor, the mixing device begins to rotate, so that the material is evenly mixed in the mixing bucket. The mixing method has many forms such as self-falling mixing and forced mixing, depending on the nature of the material and the mixing requirements. 2. Drying process: While stirring, the drying system begins to work. Usually through the hot air circulation, the hot air is blown into the mixing bucket, and the material is fully in contact with the material, so that the water in the material evaporates. At the same time, the continuous rotation of the stirring device makes the material better mixed with the hot air, speeding up the drying process. |

| 3 | structural characteristics |

|

1. High efficiency: The drying mixer can achieve uniform mixing and rapid drying of materials in a short time, improving production efficiency. 2. Environmental protection: The equipment is usually made of environmentally friendly materials, low noise and little pollution during operation, and meets the requirements of environmental protection. 3. Easy operation: The equipment is easy to operate, the control system is intuitive and easy to understand, and the user can easily master the operation skills. 4. Durability: The equipment structure is strong, smooth operation, the main components are made of wear-resistant, corrosion-resistant materials, long service life. |

| 4 | Application scope |

|

Plastic Dryer Mixer With Heating machines are widely used in pharmaceutical, food, chemical and other fields. In the pharmaceutical field, it can be used to produce a variety of granule, powder, paste and other different forms of drugs; In the field of food, can be used to produce a variety of powder, granular and other different forms of food; In the field of chemical industry, it can be used to produce various chemical raw materials and chemical products. |

| 5 | Advantages |

|

1. Good drying effect: it can quickly remove excess water in the material in a short time to obtain a dry and uniform mixture. 2. Wide range of application: can be applied to different industries, different nature of the material. 3. Easy operation: The equipment is easy to operate and easy to maintain. 4. Energy saving and environmental protection: stable operation, low noise, low pollution, in line with the requirements of energy saving and environmental protection. |

▏Product Advantage

The advantages of Plastic Dryer Mixer With Heating machine are mainly reflected in the following aspects:

| 1 | Energy-saving |

|

The drying mixer synchronizes the drying treatment during the mixing process, which significantly improves the working efficiency. Optimized hot air circulation and material mixing system to effectively reduce drying time and energy consumption. |

| 2 | Good drying effect |

|

The synergistic effect of the mixing device and the drying system makes the material evenly heated during the mixing process, ensuring uniform drying of the material and avoiding local overheating or non-drying. The drying temperature and humidity can be controlled to meet the drying requirements of different materials. 3. Wide range of application : Drying mixer is suitable for a variety of industries, such as pharmaceutical, food, chemical, etc., can handle different properties of materials, such as powder, granular, paste, etc. Different mixing parts can be replaced or operating parameters can be adjusted to meet the handling needs of different materials. |

| 3 | Easy to operate |

|

The equipment control system design is user-friendly, the operation is simple and easy to understand, and the operation can be started without complex training. High degree of automation, reduce manual operation, reduce labor intensity. |

| 4 | Safe and stable |

|

Equipment structure is strong, stable and reliable operation, reduce the failure rate. Equipped with perfect safety protection devices, such as overheat protection, overload protection, etc., to ensure the safety of the operation process. |

| 5 | Environmental protection and low noise |

|

The drying mixer has low noise during operation, reducing noise pollution. The use of environmentally friendly materials and processes to reduce the emission of pollutants such as waste gas and wastewater, in line with environmental protection requirements. |

| 6 | Easy to maintain |

|

Equipment structure design is reasonable, easy to clean and maintain. Easy parts replacement and low maintenance cost. |

| 7 | Flexibility |

|

The Plastic Dryer Mixer With Heating machine can be flexibly adjusted according to the production needs, such as adjusting the mixing speed, drying temperature and other parameters to adapt to the requirements of different materials and production scales. Can be used in conjunction with other production equipment to form a complete production line and improve production efficiency. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping