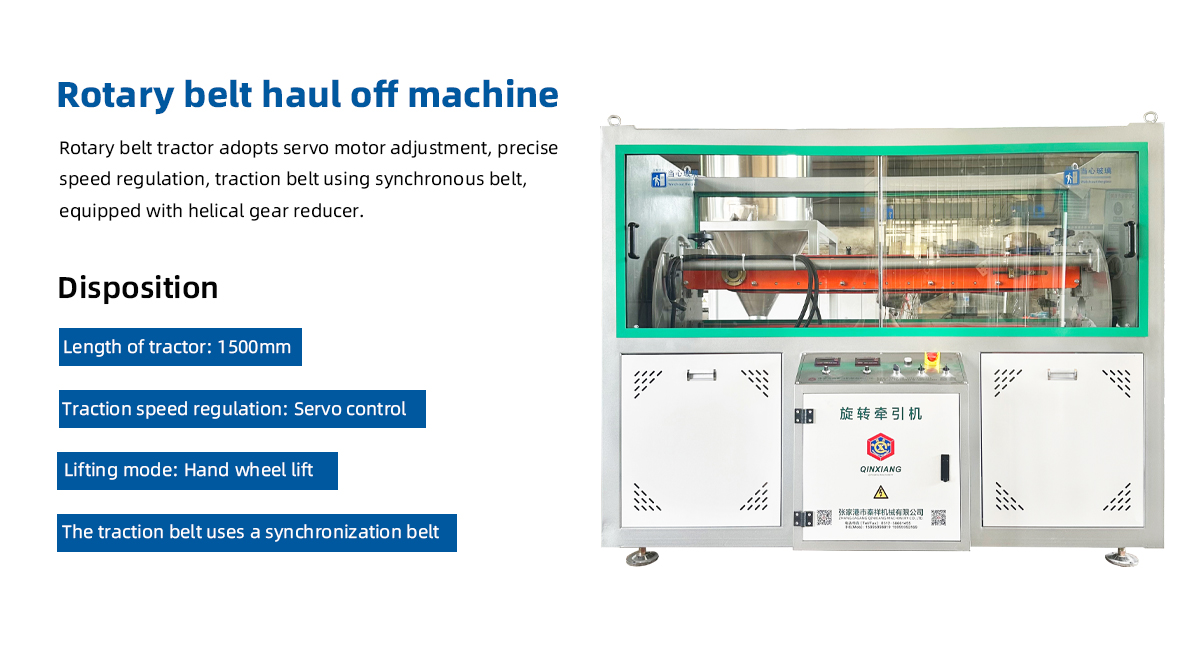

Technical Parameters

Traction frame making | 100×100mm square tube |

| Length of traction | 1500mm |

| Traction speed regulation | Servo control |

Power of traction servo motor | 1.5Kw*2 sets |

| Rotating motor | 0.75kw |

| Lifting mode | Hand wheel lifting |

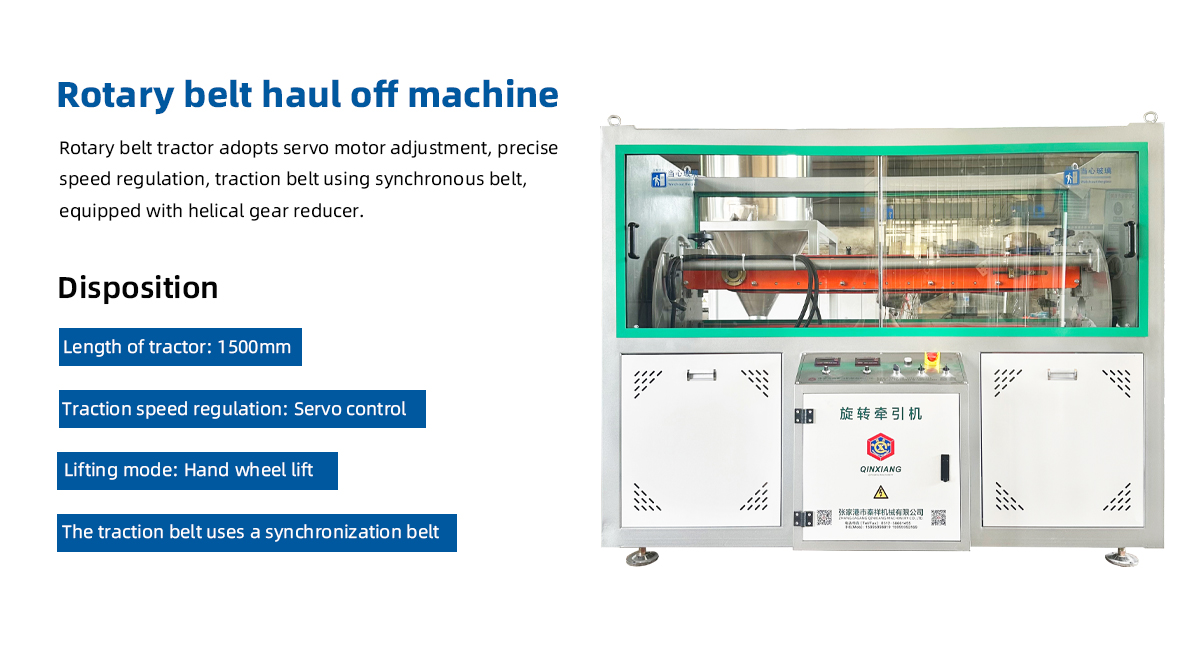

Product Photos

Rotary belt tractor, as a specific type of belt conveyor, has its unique characteristics and application scenarios. The following is a detailed introduction to the rotary belt tractor:

1. Structural Features :

Rotary belt tractor is mainly composed of power device, transmission device, traction part, frame and control system. These parts work together to achieve rotary traction of materials or products.

Rotary belt tractor can achieve 90 degrees, 180 degrees or even greater Angle turns, providing great convenience for continuous transmission of different processes.

Some advanced models of rotary belt tractor, such as the forward lifting rotary belt machine, also have electric drum for the middle drive drum, hydraulic lifting device, rotary device and other complex structures, can realize the center rotation and automatic adjustment of the horizontal Angle of the belt frame and other functions.

2. Working principle :

Similar to traditional belt machines, the working principle of rotary belt tractors also relies on the movement of the belt to drive the transportation of materials or products. The difference, however, is that the belt can achieve rotary motion to meet the traction needs under special process or space constraints.

The driving device (usually an electric motor) transmits power to the drum through the decelerating device, and the drum drives the belt for rotating motion. The material or product is placed on the belt and transported as the belt rotates.

3. Technical parameters :

Technical parameters vary according to the specific model and use, but usually include traction form (such as single traction, double traction, etc.), traction center distance, belt width, applicable traction product size, effective traction length, traction speed, maximum traction force, drive power and other indicators. These parameters are crucial for selecting the right rotary belt tractor.

4. Application Scenario :

Rotary belt tractor is widely used in a variety of occasions that require rotary traction, such as chemical industry, metallurgy, building materials, electric power and other industries. Because of its flexible turning, space saving and high conveying efficiency, it is especially suitable for conveying large quantities of materials in a narrow site.

5. Advantages and Characteristics :

Flexible turning:

large Angle turning can be achieved to meet the continuous transmission needs of different process processes.

Save space:

reduce the occupied area of equipment and improve the utilization rate of the site.

High conveying efficiency:

with high conveying speed, it can be applied to the conveying of a large number of materials.

High reliability:

dustproof, waterproof, explosion-proof and other special design to ensure stable operation of the equipment.

Cooperative Parts Supplier

Packing And Shipping

FAQ

1.Are you a factory or trading company?

Qinxiang:We are a factory.

2.Can we visit your machine operation in your factory?

Qinxiang:You can see machine operation in our factory.

3.Can the machine be customized?

Qinxiang:Yes,it can.

4.How many electric, water, air need for the machines?

Qinxiang: technical department supply the whole layout for workshop details.

5.Can I operate machine if don’t have experienced engineers?

Qinxiang: (1) short-time engineers to customer company (5-15days) (2) Year-time working as requirements

6.Any quality checking before shipment?

Qinxiang: 100% confirm, run and test machines before shipment with quality certificate.

7.How long is the guarantee?

Qinxiang: 12 months since the first day customer operates (except wear parts).

8.How can u help us when face some technical problem?

Qinxiang: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

9.Where can we get spare part?

Qinxiang: we choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.