▏Product Vedio

▏Product Introduction

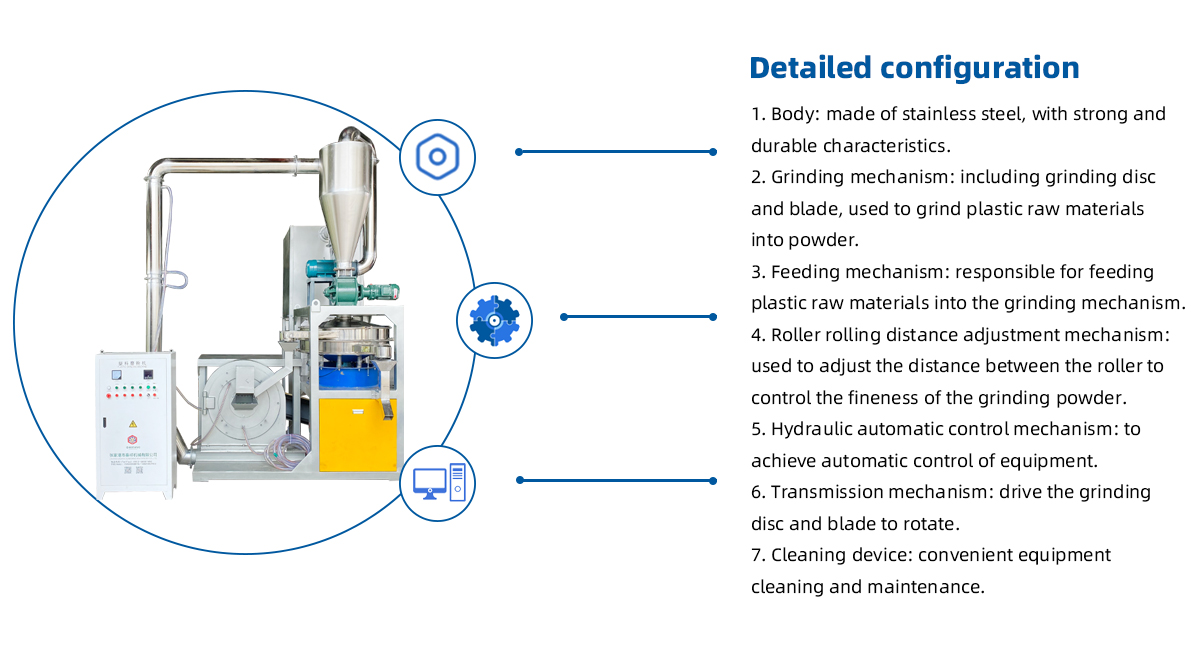

▏Main Details

▏Product Photos

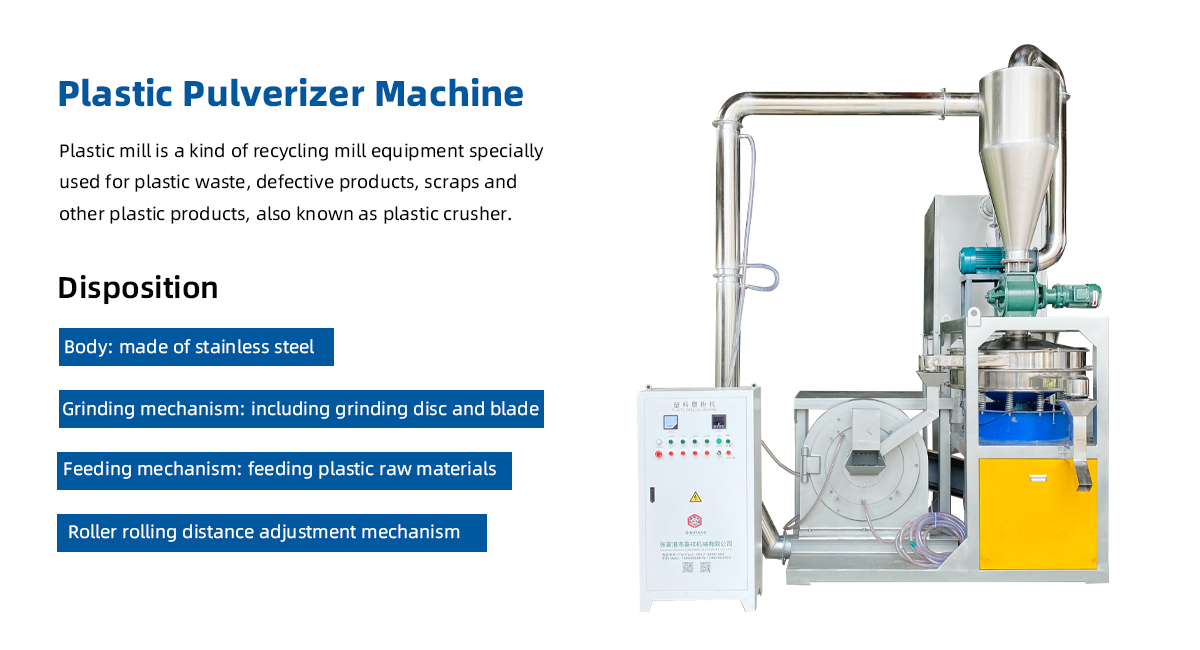

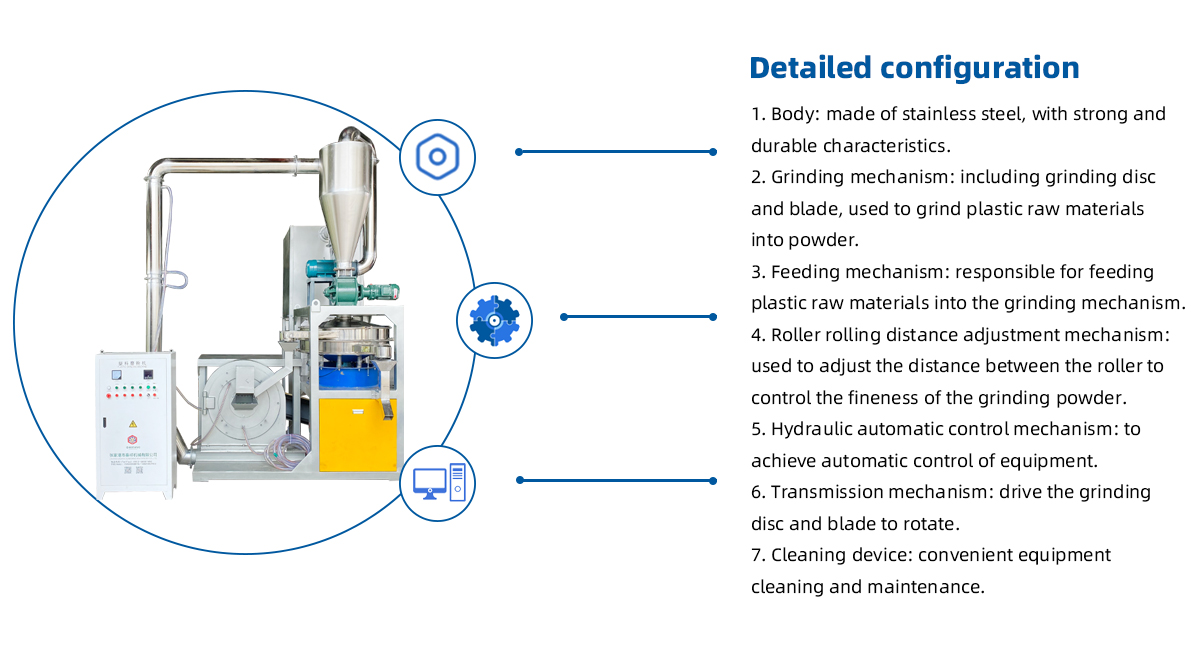

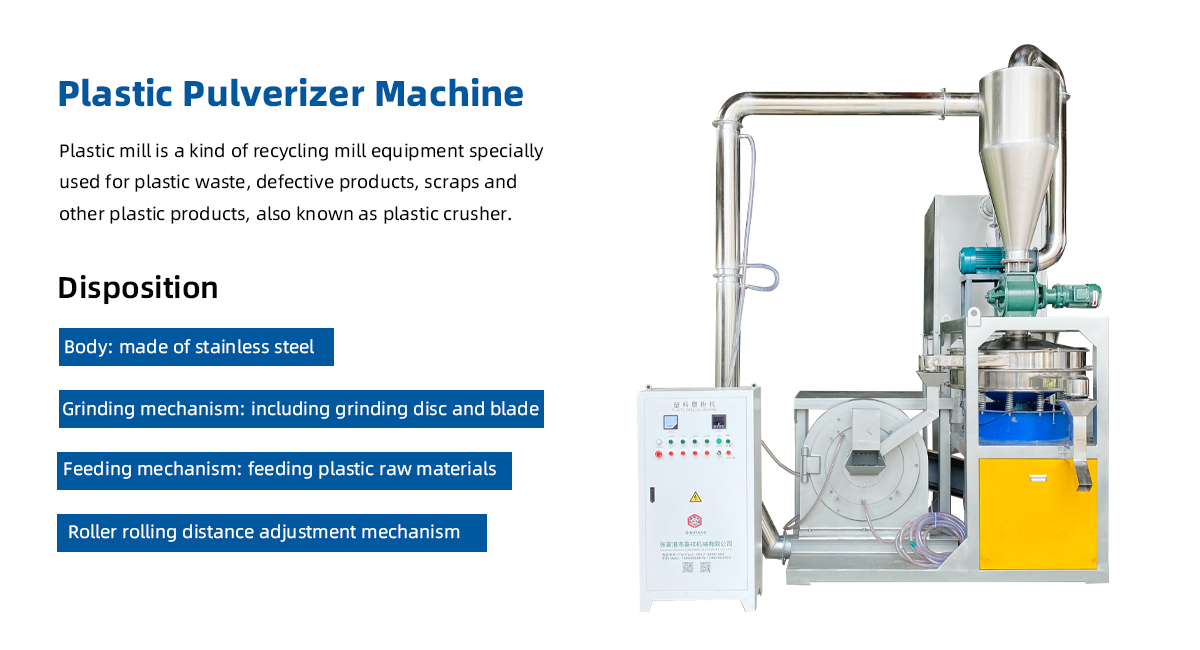

▏Plastic Pulverizer Machine: Revolutionizing Plastic Recycling and Material Processing

The Plastic Pulverizer Machine is a high-performance industrial equipment designed to transform plastic waste and raw materials into fine, uniform powders. This advanced machine is an essential tool for industries involved in plastic recycling, manufacturing, and material processing. By efficiently grinding and pulverizing various types of plastics, the Plastic Pulverizer Machine enables businesses to repurpose waste, reduce material costs, and contribute to sustainable manufacturing practices.

Key Features

| 1 | High-Efficiency Grinding |

| The Plastic Pulverizer Machine is equipped with powerful grinding mechanisms that deliver consistent and precise particle size reduction. It can process a wide range of plastics, including PVC, HDPE, LDPE, PP, and PET, into fine powders suitable for reuse in manufacturing. |

| 2 | Versatile Material Compatibility |

| The machine is designed to handle various types of plastic materials, from soft and flexible films to rigid and hard plastics, making it suitable for diverse industrial applications. |

| 3 | Adjustable Particle Size |

| With customizable grinding settings, the machine allows operators to control the fineness of the output powder, ensuring it meets specific requirements for different production processes. |

| 4 | Durable and Robust Construction |

| Built with high-quality materials and heavy-duty components, the Plastic Pulverizer Machine is designed to withstand the demands of continuous operation. Its wear-resistant blades and grinding chambers ensure long-lasting performance and minimal maintenance. |

| 5 | Energy-Efficient Operation |

| The machine is engineered to deliver high output with low energy consumption, making it a cost-effective solution for businesses looking to optimize their production processes. |

| 6 | User-Friendly Design |

| The Plastic Pulverizer Machine features an intuitive control panel that allows operators to easily adjust settings such as grinding speed, feed rate, and particle size. Safety features, including overload protection and emergency stop functions, ensure safe and reliable operation. |

| 7 | Low Noise and Dust Emission |

| The machine is designed to operate with minimal noise and dust emission, creating a safer and more comfortable working environment. |

| 8 | Customizable Options |

| The machine is designed to operate with minimal noise and dust emission, creating a safer and more comfortable working environment. |

Applications

The Plastic Pulverizer Machine is a versatile solution for a wide range of industries and applications:

- Plastic Recycling: Grinding plastic waste into fine powders for reuse in manufacturing processes.

- Manufacturing: Producing plastic powders for injection molding, extrusion, and 3D printing.

- Packaging: Processing plastic films and containers into reusable materials.

- Automotive: Recycling plastic components and producing materials for new parts.

- Construction: Repurposing plastic waste into materials for building products.

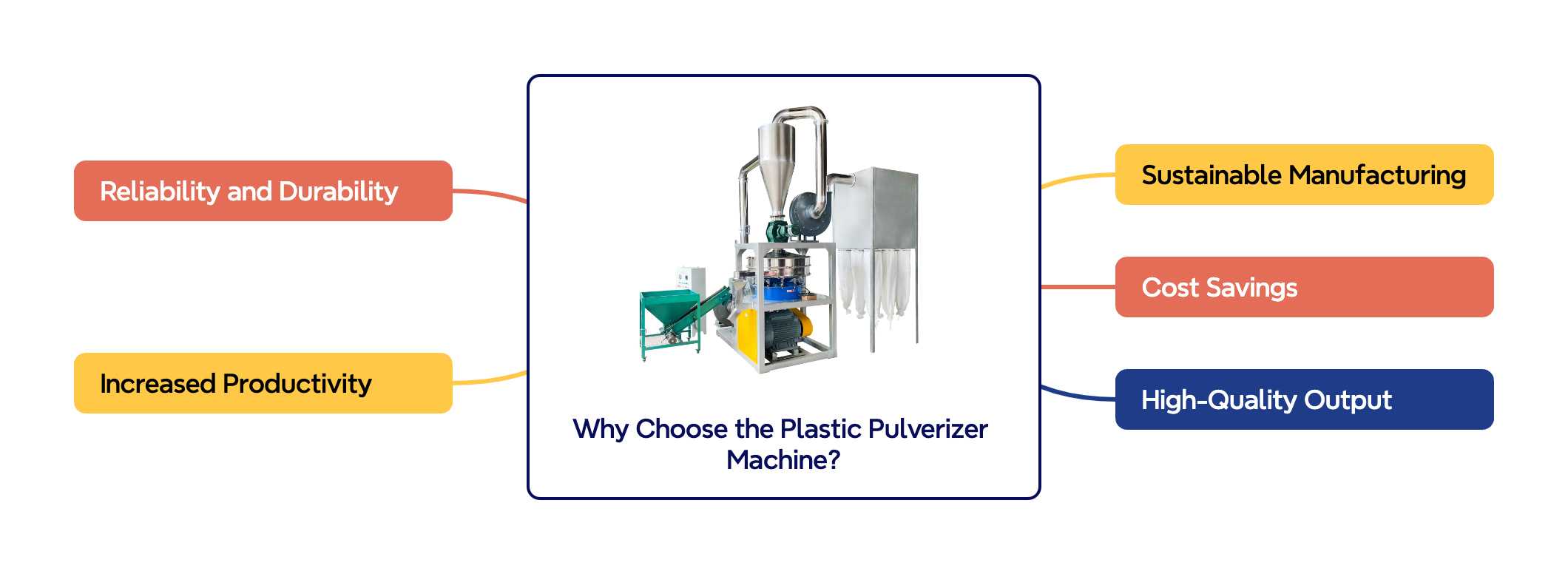

Why Choose the Plastic Pulverizer Machine?

| 1 | Sustainable Manufacturing |

| By enabling the efficient recycling of plastic waste, the machine supports environmentally friendly practices and reduces the reliance on virgin materials. |

| 2 | Cost Savings |

| The machine allows businesses to repurpose plastic waste into valuable raw materials, significantly reducing material costs and waste disposal expenses. |

| 3 | High-Quality Output |

| The precise grinding process ensures consistent particle size and quality, making the output powder ideal for various manufacturing applications. |

| 4 | Increased Productivity |

| With its high-speed grinding capabilities, the machine enhances production efficiency, allowing businesses to meet growing demand and tight deadlines. |

| 5 | Reliability and Durability |

| Built to withstand heavy-duty use, the Plastic Pulverizer Machine offers unmatched reliability and a long service life, ensuring a high return on investment. |

Technical Specifications

- Grinding Capacity: Available in various sizes to suit different production volumes.

- Material Compatibility: Suitable for PVC, HDPE, LDPE, PP, PET, and other plastics.

- Particle Size Range: Adjustable to produce powders from coarse to fine grades.

- Power Supply: Available in standard and customized power configurations.

- Construction Material: High-grade steel and wear-resistant components.

The Plastic Pulverizer Machine is the ultimate solution for businesses looking to optimize their plastic recycling and material processing operations. With its advanced technology, robust design, and user-friendly features, it delivers unmatched efficiency, quality, and sustainability. Whether you're recycling plastic waste, producing raw materials for manufacturing, or exploring new applications for plastic powders, the Plastic Pulverizer Machine is the ideal choice for your needs.

Invest in the Plastic Pulverizer Machine today and take a step toward sustainable manufacturing, cost savings, and enhanced productivity!

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping