▏Product Vedio

▏Product Overview

Plastic PVC (polyvinyl chloride) pipe production line is designed for the production of PVC material pipe and automatic production equipment. Because of its light weight, corrosion resistance, good weather resistance, easy installation and cost-effective characteristics, PVC pipe has been widely used in many fields such as water supply and drainage, power cable protection, agricultural irrigation, building drainage, chemical fluid transportation. This production line integrates advanced mechanical design and automation control technology to provide efficient, stable and flexible PVC pipe production solutions.

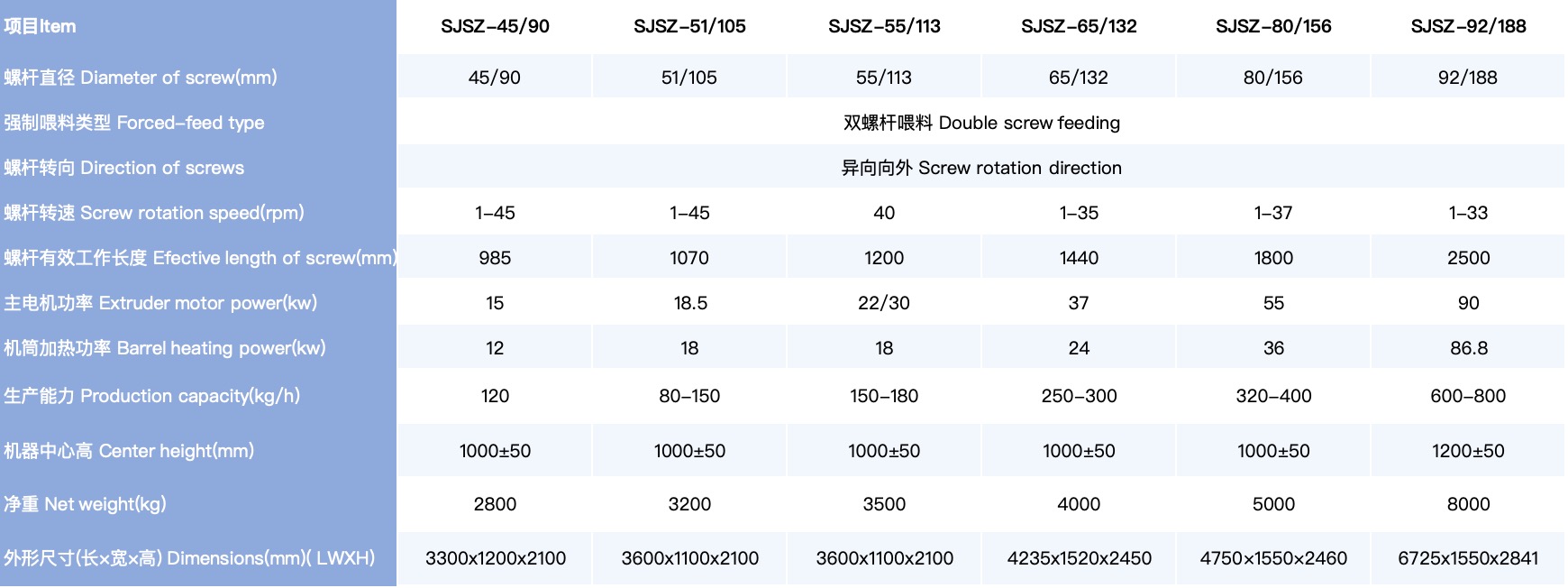

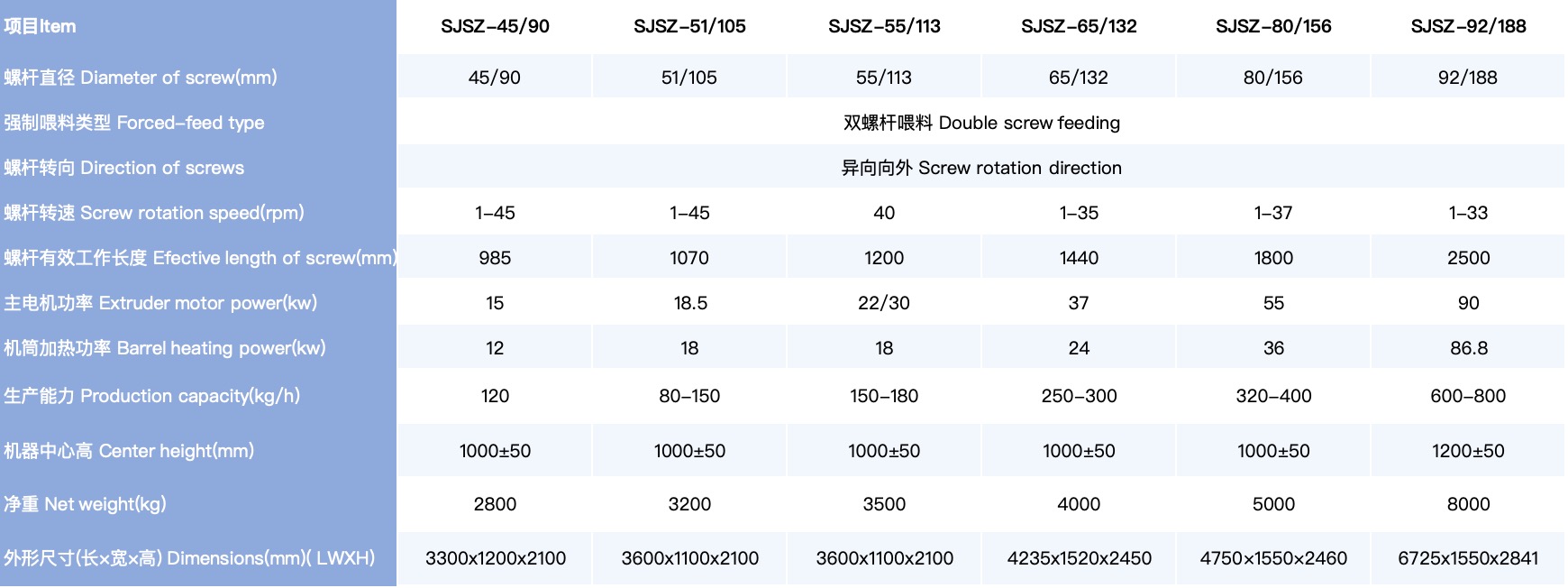

▏Configuration parameter

▏Production Line Components

PVC pipe production line is mainly composed of the following key components:

Raw material pretreatment system: including raw material drying, metering and mixing equipment.

Extruder: The core equipment is responsible for melting and extrusion of PVC raw material into tubes.

Die and head: the end of the extruder that determines the cross section shape and size of the pipe.

Vacuum setting and cooling system: to ensure rapid cooling and setting of the pipe and maintain dimensional stability.

Traction device: continuous traction of the cooled pipe to maintain the continuity of production.

Cutting machine: Automatically cutting pipes according to the set length.

Collection and stacking system: Finishing the cut pipe for subsequent processing.

Control system: Integrated PLC and HMI to realize the automatic control of the production process.

▏Raw Material Mixing Process

Raw material mixing is the PVC resin, plasticizer, stabilizer, filler and pigment are added to the mixer in a certain proportion, and each component is evenly dispersed through high-speed rotation and shearing. The mixed material should be filtered through the screen to remove impurities and ensure the smooth extrusion process.

▏Working Principle Of Extruder

Extruder is the core of PVC pipe production line, its working principle is to mix evenly PVC material into the barrel, the barrel is equipped with heating elements, so that the material melt. The molten material is pushed by the screw and extruded into a tube through the mold. The design of the screw determines the melting effect and extrusion pressure of the material, which affects the quality and output of the pipe.

▏Mold And Set Cooling

The mold is a key component that determines the shape and size of the pipe section and is usually made of high-hardness alloy steel to ensure accuracy and durability for long-term use. The extruded pipe immediately enters the vacuum setting device, and the negative pressure generated by the vacuum pump makes the pipe close to the inner wall of the setting sleeve to achieve accurate setting. At the same time, the cooling water circulation system quickly takes away the surface heat of the pipe to ensure rapid solidification of the pipe and avoid deformation.

▏Traction Cutting Process

Traction device through the chain or track clamp pipe, continuous traction at a constant speed, to maintain the continuity of the production line. The cutting machine automatically cuts the pipe according to the set length, and the pipe after cutting is sorted by the collection system for subsequent treatment.

▏Finished Product Testing And Packaging

After cutting, the PVC pipe needs to undergo quality testing, including appearance inspection, size measurement, pressure testing, etc., to ensure that the product quality meets the standards. Qualified pipes will be packaged and labeled with specifications, production date and other information for easy storage and transportation.

▏Application And Market Demand

Because of its many advantages, PVC pipe has shown a wide range of application potential in many fields. In the field of construction, PVC pipes are used in water supply and drainage systems, building drainage, wire and cable protection, etc. In the field of agriculture, PVC pipes are an important part of irrigation systems; In the chemical industry, PVC pipes are used to transport various corrosive fluids. With the acceleration of infrastructure construction and the promotion of environmental awareness, the market demand for PVC pipes continues to grow, especially in emerging markets and developing countries, and the production and application prospects of PVC pipes are broad.